Eterna Global Solutions

C-52 Block-C, Sector 80

Noida Uttar Pradesh,

201306, India

Eterna Global Solutions

C-52 Block-C, Sector 80

Noida Uttar Pradesh,

201306, India

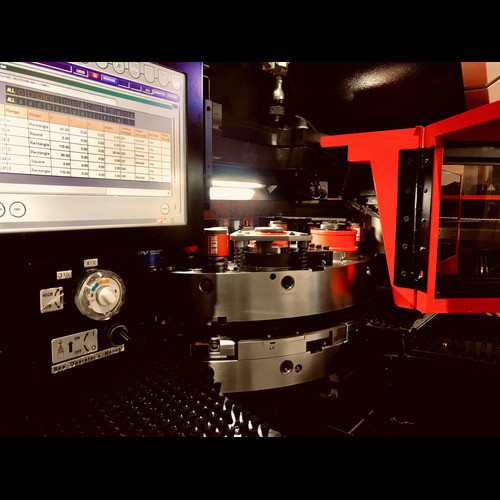

Blanking facilities at Eterna offer our customers complete and synchronized profiling facilities. Punching machines working in tandem with Laser cutting machine ranging up to 3KW allow us to produce parts from Mild Steel, Stainless Steel, Aluminum, Brass, Copper, Galvanised Steel to list a few.

Slightest of variation can halt the production at any stage. Thus, these machines are programmed using designated nesting/programming software’s to make efficient utilization of man & machine hours and raw material. At Eterna, our operators are trained to check the sheet being processed with a fine-tooth comb. Our machines go through continuous maintenance and checkup to ensure robust functioning round the clock.

With capacity to cut up to 1” thick material, we are equipped with assist gasses system on our laser machines offering smooth edges even for higher thicknesses.

An extensive tooling library for our punching machines, allow us to cater to distinctive pattern profiling and forming on turret to reduce or eliminate secondary operations.